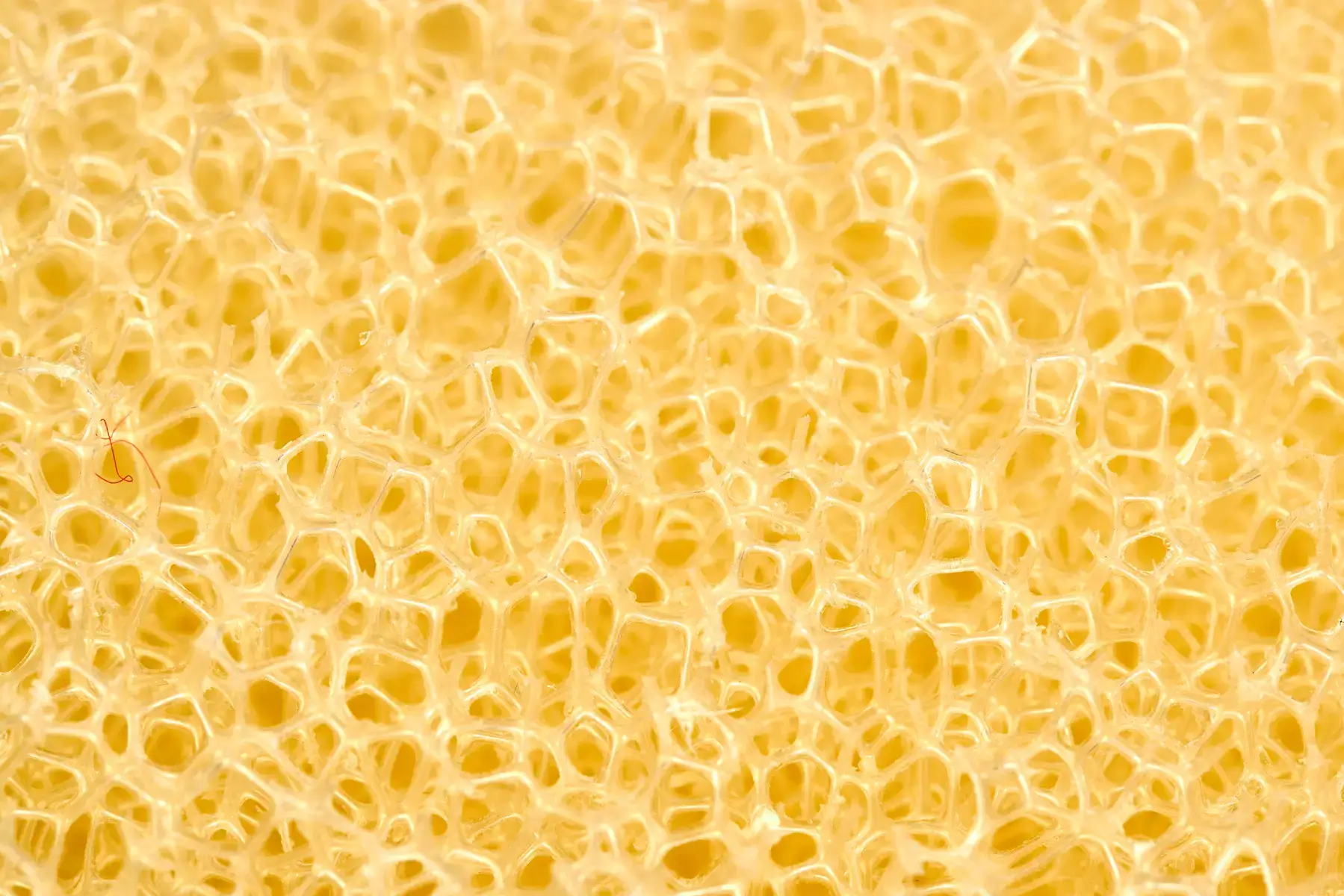

Reticulite

Reticulite is a line of premium, thermally reticulated polyester polyurethane foams. The consistent and highly porous open-cell structure unlocks a range of performance benefits and makes it an ideal choice for applications requiring controlled airflow and filtration. Our porosity polyurethane foam is used in the healthcare, automotive, and industrial sectors.

Reticulite 60 PPI

Reticulite 60 PPI (Pores Per Inch) is a thermally reticulated foam designed to achieve great outcomes for filtration applications. High in airflow and porosity, it’s often used in pre-filters, speaker grills, HVAC for dust control and other pollutants, and reservoirs. Our polyurethane foam air filters have a long lifespan and are easy to clean, making them a cost-effective solution for various industries.

-

Maximum Airflow

Large, open pores allow for unrestricted passage of air and fluids.

-

Low Pressure Drop

Ideal for applications requiring high flow rates with minimal energy expenditure

-

Sound Dampening

It can absorb lower frequencies due to the large pore size.

Reticulite 80 PPI

Reticulite 80 (Pores Per Inch) is a thermally reticulated foam designed to achieve great outcomes for filtration applications. This results in smaller pores and a slightly denser structure. Typical polyurethane foam air filter applications include medical-grade sponge, fine filtration, bio-filtration media, humidifier pads, small engine filters, acoustic panels, and cosmetic applicators.

-

Good Airflow

Great airflow and an open cell structure lend themselves to assist with many industrial filtration applications.

-

Increased Filtration Efficiency

Smaller pores mean a larger surface area for trapping fine particles in filtration applications.

-

Good Cushioning & Support

Maintains the resilient properties of polyester foam.

-

Sound Dampening

More effective at absorbing mid-range frequencies due to a smaller pore size.

-

What Is Reticulated Foam?

Reticulation is a post-manufacturing process that removes cell windows, leaving behind a network of polyurethane struts. This creates a foam that’s permeable to air and fluids with minimal resistance. Polyurethane foam for air filters will go through a reticulation process, where the foam is passed through a series of heated chambers. The heat and pressure vaporize cell windows, creating open cells that interconnect to form a rigid structure.

Learn More -

Thermal Reticulation

Reticulite is produced using thermal reticulation.. After the foam is fully cured, it’s placed within a reaction chamber, and a carefully regulated mixture of combustible gases—typically oxygen and hydrogen—is introduced and ignited. The resulting combustion quickly travels through the foam, destroying the cell membranes while leaving cell struts intact. Our porosity polyurethane foam is available in various pore sizes and can be used for a variety of applications, from filtration to flame-retardant barriers.

The Best in Airflow and Filtration.

Learn how Reticulite can support your product needs.

Get in Touch