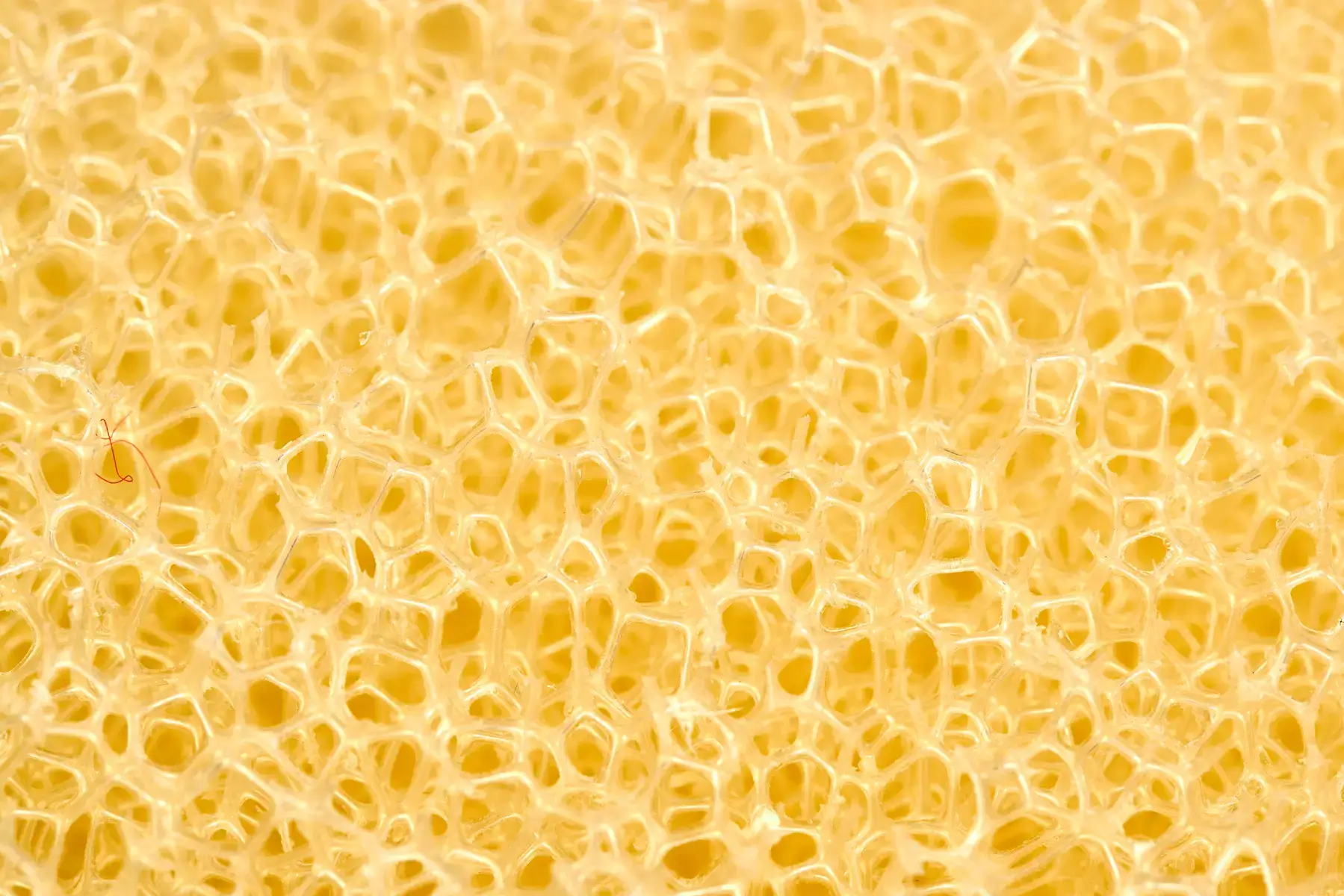

Reticulated Foams

Reticulation removes foam cell windows, leaving only the struts intact. This dramatically alters the foam’s properties to create highly porous materials with air permeability, flexibility, and other unique characteristics. WT Burnett uses advanced techniques, including in-situ and thermal, to create specialized foams for a wide range of applications.

-

In-Situ Reticulated Foams

In this method, the open-cell structure develops during the foaming process. We can tailor porosity and airflow characteristics during manufacturing, often resulting in a more interconnected and uniform structure. In-situ reticulation is a strong choice for foams with specific filtration or fluid management properties.

-

Thermally Reticulated Foams

In this method, foam is placed within a chamber, and gases ignite to remove cell walls. Grades with pores per inch (PPI) range from 10 to 100 in both ether and ester foams. The consistent porosity enables these materials to be used in a wide range of applications requiring high airflow, such as filtration, acoustics, and fluid transfer.

Choosing the Right Method for Your Needs

Whether you choose in-situ or thermal reticulation depends on several factors, including desired properties (e.g., pore size, airflow, mechanical characteristics), application and chemistry. Our team can help you determine the most reticulation that’s right for your performance and application demands. Contact us today to learn more.

Get in Touch